Why Plastic Injection Molding Is Important for Accuracy and Longevity

Why Plastic Injection Molding Is Important for Accuracy and Longevity

Blog Article

The Future of Plastic Shot Molding: Patterns and Technologies to View

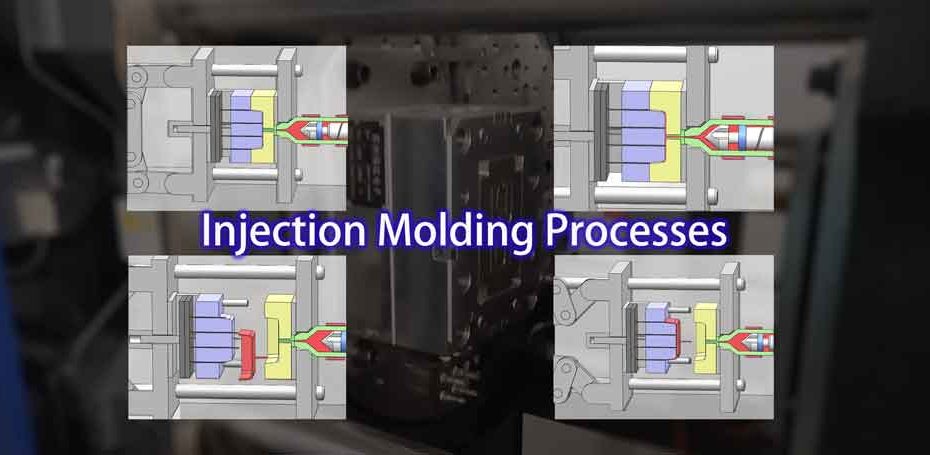

As the plastic injection molding market progresses, a number of crucial patterns are arising that assurance to reshape its landscape. Automation and clever production strategies are readied to boost efficiency, while the change towards lasting products reflects a growing ecological awareness. Developments in 3D printing are leading the method for extraordinary layout versatility. However, these innovations additionally bring forth difficulties that need cautious consideration. Comprehending just how these components will connect and influence future methods is important for stakeholders wanting to browse this transformative period efficiently.

Automation and Smart Production

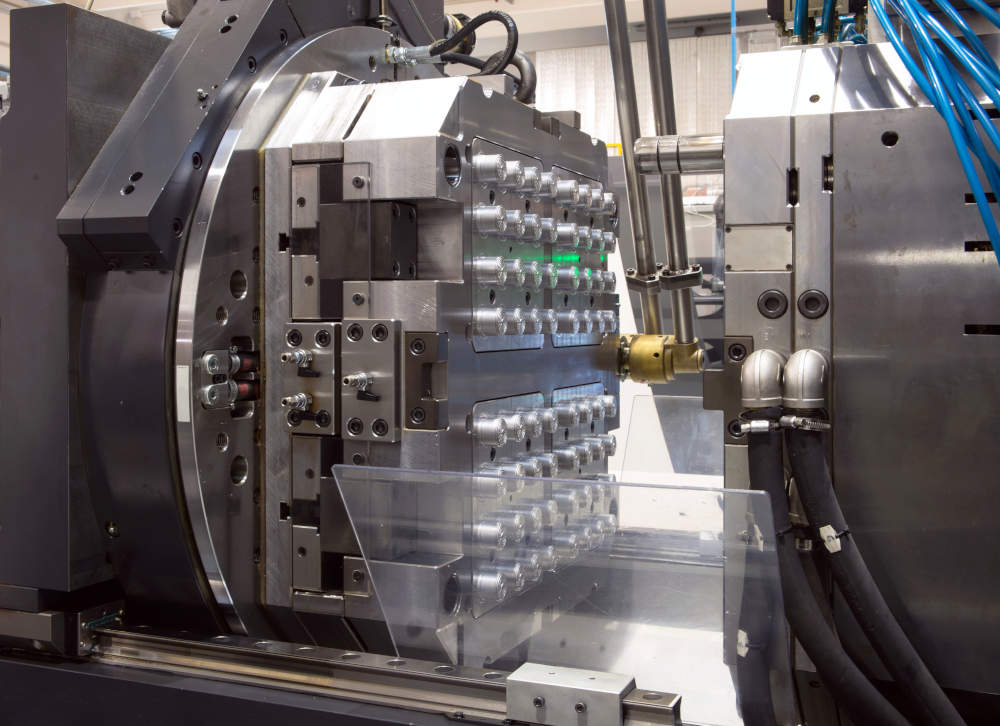

As the plastic shot molding industry advances, automation and wise manufacturing are taking spotlight, revolutionizing production processes - Plastic Injection Molding. The combination of sophisticated modern technologies such as robotics, IoT (Internet of Points), and fabricated knowledge is enabling producers to boost effectiveness, reduce operational costs, and enhance product high quality. Automated systems improve workflows, minimizing manual intervention and enhancing throughput, which is essential in fulfilling the climbing demand for quick manufacturing cycles

Smart producing innovations facilitate real-time surveillance and information evaluation, enabling business to optimize machine efficiency and forecast maintenance requirements. This positive approach not just reduces downtime however additionally expands the lifespan of tools. The use of joint robotics, or cobots, boosts the versatility of manufacturing lines, enabling workers and equipments to operate side by side safely and effectively.

The adoption of automation in plastic shot molding is not merely a fad however a tactical necessary for companies aiming to stay affordable in a worldwide market. By utilizing these technologies, makers can accomplish higher accuracy, lower waste, and adapt promptly to transforming client demands, placing themselves for lasting development in an increasingly automatic future.

Lasting Products and Practices

The press in the direction of automation and smart production has actually paved the means for a greater emphasis on sustainable materials and techniques within the plastic shot molding sector. Companies are increasingly seeking environmentally friendly alternatives to conventional petroleum-based plastics, causing the adoption of recycled and bio-based products. These sustainable products not just minimize environmental influence however also straighten with customer need for greener products.

Furthermore, partnership in between producers, material suppliers, and ecological organizations is cultivating advancement in the development of sustainable materials that fulfill efficiency criteria without jeopardizing high quality. As guidelines around plastic usage become more stringent, the industry is poised to adapt by accepting these sustainable techniques, making certain lasting feasibility and minimizing reliance on non-renewable resources. The integration of sustainability right into plastic shot molding is not merely a trend; it is coming to be a necessary part of corporate obligation and functional quality.

Advancements in 3D Printing

Recent advancements in 3D printing modern technology are considerably transforming the landscape of plastic shot molding. The integration of additive production procedures enables for the fast prototyping of intricate geometries that were when tough or difficult to accomplish through standard approaches - Plastic Injection Molding. This ability not only speeds up product advancement cycles yet likewise minimizes material waste, straightening with the expanding need for sustainable production methods

In addition, the appearance of crossbreed production techniques, which incorporate 3D printing and injection molding, provides producers the capacity to produce detailed layouts while maintaining the performance of mass production. This method allows the manufacturing of personalized parts customized to specific customer demands without giving up the speed and scalability that injection molding gives.

Furthermore, improvements in materials, such as high-performance polymers and composites especially created for 3D printing, are boosting the useful abilities of printed parts. These materials can withstand better stress and anxiety and show improved anchor thermal buildings, making Check This Out them appropriate for more requiring applications.

As 3D printing proceeds to develop, its integration right into plastic shot molding processes assures to improve performance, minimize prices, and foster technology in item design, placing manufacturers to better meet the obstacles of an open market.

Information Analytics and IoT Combination

Information analytics and the integration of the Internet of Things (IoT) are changing plastic shot molding by offering manufacturers with extraordinary insights right into their operations. By leveraging real-time data collected from interconnected equipments and sensing units, manufacturers can check performance metrics, identify inefficiencies, and maximize manufacturing processes. This data-driven approach helps with anticipating maintenance, lowering downtime and prolonging tools life-span.

Additionally, IoT combination enables boosted quality assurance. By continuously tracking variables such as cycle, temperature level, and stress times, suppliers can swiftly find deviations from developed specifications and make modifications in real time. This not only improves item uniformity but also reduces waste and scrap rates.

The fusion of information analytics and IoT technologies also empowers manufacturers to adopt even more dexterous production techniques. With access to thorough information analytics, companies can react to market needs with better flexibility, changing manufacturing routines and arrangements as required. This versatility is vital in a swiftly altering production landscape.

Personalization and Layout Adaptability

Exactly how can customization and layout flexibility continue reading this improve the competition of plastic injection molding? In a significantly diverse market, the ability to use tailored services is critical. Personalization permits manufacturers to meet certain customer demands, suiting distinct measurements, shapes, and functionalities that typical products might not fulfill. This versatility not only fosters client commitment yet likewise opens up avenues for brand-new service chances across different fields, from automotive to durable goods.

Innovations in design technologies, such as computer-aided layout (CAD) and fast prototyping, more strengthen this pattern. These devices allow designers to create complex patterns and complicated geometries, which can be seamlessly integrated into the production process. As a result, suppliers can respond swiftly to altering consumer choices and market demands.

Furthermore, the implementation of modular tooling systems enhances design adaptability, permitting quicker modifications in between different product styles without extensive downtime. This versatility can lead to decreased preparations and reduced production expenses, making companies much more affordable and nimble. Inevitably, accepting personalization and layout versatility in plastic injection molding not only boosts product offerings but likewise reinforces market positioning in an ever-evolving landscape.

Final Thought

The future of plastic shot molding is characterized by significant improvements in automation, lasting practices, and cutting-edge products. The combination of IoT and data analytics will improve functional efficiency and predictive maintenance. The fostering of bio-based and recycled products, along with progression in 3D printing, will promote sustainability within the market. Modification through modular tooling and rapid prototyping will certainly enable producers to remain competitive and receptive to the vibrant needs of the marketplace.

The future of plastic injection molding is identified by significant advancements in automation, sustainable methods, and innovative materials.

Report this page